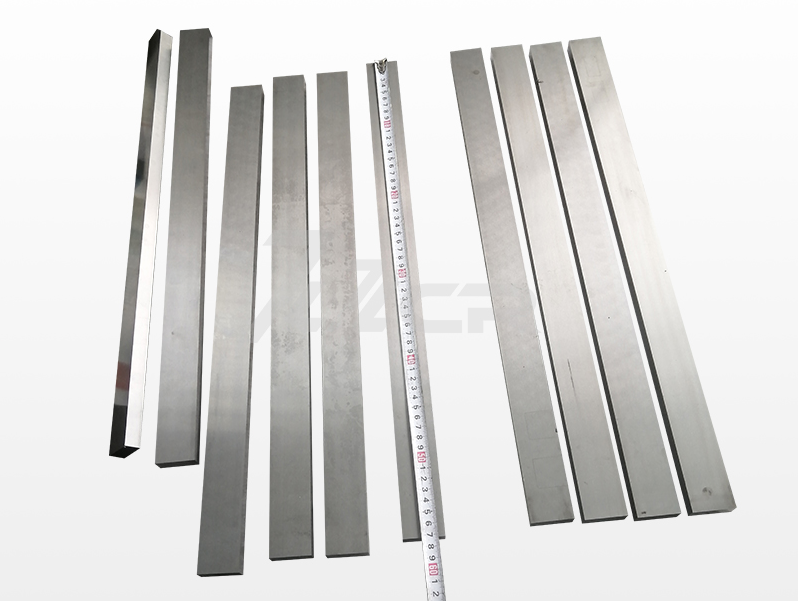

ʻO nā kākela Carbiden ke hana nuiʻia o WC Tungsten Carbide a me CO COPORT PREET

ʻO kekahi o nā mea waiwai nui o nā mea kīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīwīʻia ma muli o konaʻano huliʻana o nā papa (a iʻole nā'āpana. He paʻakikī koʻikoʻi ka crabiden crabide, lole lole maikaʻi, kiʻekiʻe elalition, kiʻekiʻe kūpono kūpono, heʻano haʻahaʻa haʻahaʻa

He aha nā kumu no kaDesurofingo nā'ōpala carbide carbide? E pane maiʻo Chuangrii carbide i hope aʻe:

(1)ʻO ka papa o ke kāʻei o ka carbet carbedeʻaʻole i mālamaʻia a iʻole i paʻiʻia ma mua o ka hoʻolimalimaʻana, a he maʻa i ka ikaika o ka brazing ma ka umauma o ka weld.

(2)DesurofingE hele mai nō hoʻi i ka wā i kohoʻia ai ka luna brazing a hoʻohanaʻoleʻia,ʻaʻole hiki i ka borax ke hana i ka brazing ma luna o ka brazedDesurofinghele maiʻo Phenonied.

)Desurofinge hele mai ana inā he kiʻekiʻe loa ke ea. Ka nui loa i hiki i ka nui ke hiki ke loaʻa i ka pahuhopu i ka weld. Ke hoʻohana nei i ka zinc-i loaʻa i ka metala brazing e hāʻawi i ka weld aʻulaʻula aʻulaʻula paha. Ke haʻahaʻa loa ka mahana o ka brazing, e hanaʻia ka meaʻala a me keʻano o ka weld, a e uhiʻia ka loko o ka weld ʻO nā kūlanaʻeluaʻelua e hōʻemi i ka ikaika o ke kupu, a he maʻalahi ia i ka deweld i ka wā i koiʻia ai a hoʻohanaʻia paha.

(4) i ke kaʻina hana brazing,ʻaʻohe manawa i ka hanaʻana a iʻole ka hopena o ka slag slag, no laila e hōʻemi ai i ka ikaika o ka weld a me nā kumuDesurofing.

Post Time: Aug-28-2024